Shinhan Financial Group Sustainability Policy Framework

To prevent confusion and clarify the meaning of the terms used in this document, ‘Shinhan Financial Group Sustainability Policy Framework,’ we define the terms used to identify the Group and Asset classes covered thusly.

- Group

All Shinhan companies, including Shinhan Financial Group and subsidiaries Holding Company

Shinhan Financial Group Subsidiary Shinhan Bank, Shinhan Card, Shinhan Investment, Shinhan Life Insurance,

Shinhan BNP Paribas Asset Management, Shinhan Capital, Jeju Bank, Shinhan Savings Bank - Asset classes covered

All internally managed assets are covered: Listed Equity, Fixed Income, Private Equity, Infrastructure, Property, Derivatives & Alternatives

- 1.Need for Environmental & Social Risk Management

- 2.Purpose and Principles of Environmental & Social Risk Management

- 3.Environmental & Social Risk Management System

- 4.Information Disclosure

- 5.Reinforcement of Capabilities

1. Need for Environmental & Social Risk Management

Due to the emergence of diverse stakeholders and global issues such as climate change, there is a higher level of demand for corporate social responsibility (CSR). Expectations for socially responsible management from financial institutions are also rising, particularly when it comes to financing. In addition to traditional risk management vis-à-vis investment recoupment, considerations about the environmental and social effects are becoming increasingly important factors that need to be reflected when making decisions about loans and investments.

In response to such changes in the business environment, it is necessary to define the Group's task and specify the working process regarding the essential environmental and social aspects that need to be managed. The Group Environmental & Social Risk Management Policy Framework was established to enable consistent policy operations across the Group.

2. Purpose and Principles of Environmental & Social Risk Management

2.1. Purpose

Environmental and social risk management refers to a series of activities that recognizes, evaluates, and manages the effects that financing recipients' economic activities have on the environment and society.

Therefore, the purpose of environmental and social risk management is to preemptively manage a multitude of potential risks by considering the environmental and social effects of the Group's financing and carrying out management activities, and in doing so, support the stable growth of the Group.

2.2. Principles

The principles of environmental and social risk management are as follows.

- [Principle 1] We recognize environmental and social risk management is an important factor in realizing sustainable business practices.

- [Principle 2] We operate a framework for reviewing and inspecting potential environmental and social risks that may occur when making business decisions.

- [Principle 3] We select and manage areas of interest that may be sensitive or harmful from an environmental or social perspective.

- [Principle 4] When providing financial services that have a major impact on the environment or society, such as large-scale project financing, we will seek to minimize the risks by assessing the risks and preparing mitigation measures.

- [Principle 5] We will disclose key policies related to environmental and social risk management to strengthen communications with internal and external stakeholders.

- [Principle 6] We will strive to expand awareness of environmental and social risks and enhance management capabilities with participation from all employees.

3. Environmental & Social Risk Management Framework

The Group Environmental & Social Risk Management Framework consists of management of areas of interest (including financing exclusions and conditions) and tasks related to environmental and social risk review.

Specific processes for the management of areas of interest and environmental and social risk review are defined through a separate work manual.

3.1. Management of Areas of Interest

The Group selects and manages areas of interest that may be sensitive or harmful from an environmental or social perspective. Subsidiaries will follow the minimum selection criteria put forward by the Holding Company, but may add their own areas of interest based on the priorities, main business or product area, etc. of each Subsidiary's portfolio.

3.1.1. Selection Criteria

The following factors must be considered when selecting areas of interest.

- ① Environmental Impact

- Industries dealing with hazardous substances can endanger the survival of surrounding ecosystems and communities due to pollutant leaks or accidents, if proper management and preventive measures are not in place. In general, as the size of the project increases, the amount of hazardous substances to be treated and the amount of pollutants to be discharged are also increased, thus more stringent environmental management is required.

- • Aspects on Greenhouse Gas Emissions

- GHG emissions from energy supply and industrial activities are among the leading causes of climate change. Climate change due to greenhouse gas emissions is a top priority concern for mankind. It has attracted the interest of the international community, and various aspects of regulations are being tightened to reduce greenhouse gas emissions.

- ② Social Impact

- Human rights are important values to be considered in all industrial sectors, and their impact on human rights may vary, depending on the type of business or region. Therefore, depending on the nature of the project, it is necessary to pay attention to the impacts taking place on relatively vulnerable groups such as indigenous people, children, and women.

- • Adverse Impact on Local Communities and Habitats

- Projects that require large-scale project sites or projects with a large radius of influence may have an impact on the local communities and habitats of the various stakeholders, in addition to the environmental impact from pollutant emissions. In particular, if there exist major cultural heritages at the project site, a preliminary study shall be required to prevent damage to the cultural heritage.

- • Occupational Health and Safety (OHS)

- Every worker has the right to pursue physical and mental health in a safe and hygienic work environment and companies must take appropriate measures to ensure the safety and health of workers within the ambit of the law and through general employment practices. In particular, safety and health of the workers should be considered as a priority particularly in safety and life-threatening work environments such as during the handling of hazardous materials.

3.1.2. Subjects

Group-wide areas of interest are as follows.

1. Large-scale agricultural and food crop production

- (1) Risks

- ① Environmental Impact

As the size of the crop grows, the requirement for necessary agricultural chemicals (fertilizer, insecticide, pesticide, etc.) increases simultaneously. Some chemicals may get adsorbed by the soil particles and hence cause soil contamination. Chemicals released from the soil due to rainfall and the like, may cause surface and groundwater contamination. The use of surface water and groundwater as a source of water can have a negative impact on humans.

- ② Adverse Impact on Local Communities and Habitats

The use of large amounts of irrigation water for large-scale crop cultivation can lead to a shortage of living water for local residents in areas where limited water resources are available, and can also affect relevant ecosystems due to changes in the water levels of reservoirs and lakes.

If the same crops are continuously grown on the same soil, uneven consumption of nutrients and fertilizer accumulation may cause degradation in the productivity of soil and harm the biodiversity of the topsoil and subsoil layer.

There are also cases where the cultivation of crops, such as large sugarcane cultivation for producing ethanol fuel and cultivation of palm trees for palm oil production, is used for biomass rather than for food. Cultivation of crops for large-scale biomass power generation can have a negative impact on existing agricultural land shortages and surrounding biodiversity.

- ① Environmental Impact

- (2) Relevant Industry

- ① Production of large-scale annual crops

The term ‘annual crops’ refer to crops that go from sowing to harvesting within a year. This is the case for large-scale annual crops, which are used as major foodstuffs, such as cereals, legumes, and stem plants.

- ② Production of large-scale perennial crops

Perennial crops refer to crops that can grow and propagate spontaneously without sowing every year. For instance, the large-scale cultivation of fruit, medicinal plants, sugar cane, and coffee.

- ③ Production of large-scale crops for the production of vegetable oil and fat

It is a large-scale cultivation setup of annual and perennial crops, which is not for the production of food resources but for that of vegetable oil and fat production, biomass fuel production and so on.

- ① Production of large-scale annual crops

- (3) Korea Standard Industry Classification (from 10th revision notification)

- Classification codes and item names are based on the sub-category.

Classification Code Item Name A0111 Growing grains and other food crops A0112 Growing vegetables, flowers and seedlings A0113 Growing fruit, beverage and spice crops A0114 Other crops A0115 Farming greenhouse crops - (4) Monitoring Items

- Level of soil contamination

- Level of water pollution

- Amount of used agricultural chemicals such as pesticides, fertilizers, pesticides, etc.

- Ecosystem impact on the surroundings of the large farmland in question

- Water consumption

- Amount of energy used (such as for operating a constant temperature and humidity device in a vinyl greenhouse)

- For biomass crop cultivation, whether it is a lack of nearby farmland and food resources

2. Forestry

- (1) Risks

- ① Environmental Impact

When processing with collected wood, there may be a risk of environmental pollution due to the use of harmful substances, such as preservatives and polishes.

Most boards and particle-based products require adhesives, waterproofing resins, etc. which can further cause water pollution problems.

Production of pulp and paper requires significant amounts of water and power. Hazardous substances used during the manufacturing process of products may affect water quality.

- ② Adverse Impacts on Local Communities and Habitats

Large-scale logging causes irreparable damage to biological habitats, and the loose soil from which trees are removed increases the risk of flooding and landslides due to soil erosion.

- ③ Occupational Safety and Health

Equipment used for logging and wood processing is usually heavy, sharp, and can lead to serious injury to the operator, if not properly handled.

It requires to have measures of fire prevention because wood byproducts such as sawdust and chemicals that are used in wood processing are prone to fire.

- ① Environmental Impact

- (2) Relevant Industry

- ① Production of forest derived products such as logging

Collection, harvesting, transportation of forest products. The collection and transportation of wood before primary processing is classified as forest product production.

- ② Board and particle based product manufacturing

✓ It is the case where plywood and cork products are produced by using the byproducts generated during the processing of wood such as MDF (plywood mixed with sawdust and wood) and OSB (board compressed with waterproof resin and wood byproducts).

- ③ Production of lumber and wood based products

It includes primary processing industries such as sawmills, and secondary processing industries that manufacture finished wood products such as furniture and laminated plywood. It also includes cases where only processed wood and wood products are further processed for preservation.

- ④ Pulp and Paper Industry

It includes pulp and paper mills and recycling facilities for pulp and paper.

- ① Production of forest derived products such as logging

- (3) Korea Standard Industry Classification (from 10th revision notification)

- Classification codes and item names are based on the sub-category.

Classification Code Item Name A0202 Logging business A0203 Forest products business C1610 Lumber and wood processing C1621 Manufacturing of laminates, plywood and reinforced wooden products C1623 Manufacturing of wooden boxes, drums and reels C1629 Manufacturing of other wooden products C1630 Cork and fabric products manufacturing C1711 Pulp manufacturing C1712 Paper and paperboard manufacturing C1721 Manufacturing of corrugated paper and corrugated products C1722 Manufacturing of paper bags, cardboard boxes and paper containers C1790 Manufacturing of other paper and cardboard products C3230 Manufacturing of wooden furniture - (4) Monitoring Items

- In case of large-scale logging, the impact on local habitat and ecology

- Level of water pollution

- Water and energy usage

- Logging area and whether it includes the habitat of protected species at the logging site

- Fire prevention measures

- Measures for workers’ safety and health

3. Manufacturing Chemical Substances

- (1) Risks

- ① Environmental Impact

During the chemical manufacturing process, volatile organic compounds, fumes, benzene, various other types of hydrocarbons and harmful gas may be generated in addition to air pollutants such as sulfur oxides, nitrogen oxides, and particulate matter generated from fossil fuel combustion. Air pollutants that are not appropriately treated can also have a significant impact on the health of nearby residents.

Wastewater from the chemical manufacturing process contains various harmful substances that are fatal to humans, animals and plants. When discharging and releasing the wastewater from the chemical plant to the water system, it is required to have an advanced wastewater treatment capability.

While manufacturing chemical products, various additional substances such as catalyst, organic solvents, acidic and basic solution are added to produce the specified products and toxic wastes such as waste catalyst, waste oil and waste acid are generated after production. During the process of storing, transporting, and disposing of waste, it is essential to take measures to prevent accidents and thus minimize environmental impacts.

- ② Greenhouse Gas Emission

Chemical manufacturing requires a multitude of processes, such as material synthesis, polymer synthesis, and also for high-temperature / high-pressure working environments, starting from the cracking stage of crude oil to molecular decomposition reaction. In order to meet these production conditions, a large amount of energy is required, which soon causes large-scale greenhouse gas emissions.

Refining and classification of crude oil and the liquefaction and gasification of coal happens in working environments at high temperatures, and the use of large-scale fossil fuels brings about greenhouse gas emissions.

- ③ Occupational health and safety

Chemically reactive and toxic chemicals are mainly used in chemical plants. In many cases, it is operated under high temperature and high pressure conditions in the manufacturing process. Operators should be familiar with the safety instructions. When operating the plant, measures should be taken to mitigate the risks to workers.

Due to the high temperature and pressure conditions of the manufacturing process and the handling of highly reactive chemicals, it is very likely that small fires will lead to large explosions in chemical plants. Such accidents in chemical plants can cause extensive and fatal damage, including the spread of toxic substances and destruction of surrounding areas, as well as human casualties.

- ① Environmental Impact

- (2) Relevant Industry

- ① Manufacturing of basic chemicals

Basic chemical is referred as a single chemical substance (base material with low molecular weight such as ethylene, propylene, etc.) that becomes a raw material of polymer through processes such as pyrolysis and distillation. It is a raw material of almost all the chemical products such as synthetic rubber and plastic. Of these, basic organic chemicals are referred to as carbon-based chemicals, while petrochemical basic chemicals are also included in the category of basic organic chemicals.

Basic inorganic chemical is referred as a non-carbon-based basic chemical substance, and it is the case of producing caustic soda (NaOH), sulfuric acid (H2SO4), hydrochloric acid (HCl), etc

- ② Manufacturing of chemical products

(Manufacture of synthetic rubber and plastics) it refers to the production of polymeric materials, which are raw materials for synthetic rubber, synthetic resin and plastic, through the use of basic chemicals, and the production of rubber / plastic products of finished products.

(Manufacture of other chemicals) it refers to the production of basic chemicals such as insecticides, fertilizers and pesticides, or chemical products not included in the synthetic rubber and plastics categories.

(Manufacture of refined petroleum products) it is mostly refinery products. It refers to the process of refining crude oil to produce fuel such as gasoline, diesel, kerosene and heavy oil, and produced finished products (engine oil, lubricant, grease, etc.) through oil refining.

- ① Manufacturing of basic chemicals

- (3) Korea Standard Industry Classification (from 10th revision notification)

- Classification codes and item names are based on the sub-category

Classification Code Item Name C1910 Manufacturing of coke and briquettes C1921 Refining of crude oil C1922 Reprocessing of petroleum refined products C2011 Manufacturing of basic organic chemicals C2012 Manufacturing of basic inorganic chemicals C2013 Manufacturing of inorganic pigments, dyes, softeners and other colorants C2020 Manufacturing of synthetic rubber and plastic materials C2031 Manufacturing of fertilizer and nitrogen compound C2032 Manufacturing of sterilization, pesticide and agricultural chemicals C2041 Manufacturing of inks, paints, coatings and similar products C2042 Manufacturing of detergents, cosmetics and polishes C2049 Manufacturing of other chemical products C2050 Manufacturing chemical fibers C2211 Production of rubber tire and tube C2219 Manufacturing of other rubber products C2221 Manufacturing of primary plastic products C2222 Manufacturing of plastic products for construction works and projects C2223 Manufacturing of plastic products for packaging C2224 Manufacturing of plastic products for the assembly of machinery equipment C2225 Manufacturing of plastic foam molding products C2229 Manufacturing of other plastic products - (4) Monitoring Items

- Concentration and discharge of air pollutant emissions

- Concentration and discharge of water pollutants

- Whether wastes are treated appropriately or not

- Prevention of environmental / safety accidents

- Measures for detecting Environmental / safety accidents

- Measures for environmental / safety accident response

- Energy consumption and greenhouse gas emissions

4. Mining Industry

- (1) Risks

- ① Environmental Impact

When mining coal, minerals, and stone, there are various methods such as longwall mining, stepping mining, slope mining, dredging mining, and solution mining depending on the mining subject and depth of mining required. It can be divided into underground mining (mining through an underground pit) and open-pit mining (removal of a pit without removing a pit and mining from the surface immediately). The common risk in these methods is the water pollution caused by heavy metals. During mine digging work, a large amount of water is required foruse in the mines for various purposes such as damping of friction and removal of scattered dust during drilling. Water flowing into the mine is likely to be exposed to heavy metals. If the mine wastewater generated by this process flows into the soil and groundwater, it may have an adverse effect on the environment.

In the case of open-pit mining, airborne pollution may cause damage to a large area due to the scattered dust generated during the mining process. Heavy metal leachate with rainwater may also come to the surface of the exposed mine. In the abandoned mines after a project is over, semi-permanent water pollution may occur due to continuous inflow of rainwater and groundwater.

- ② Adverse Impact on Local Communities and Habitats

In addition to the impact on habitat due to water pollution, there may be damage to the surrounding area from the continuous noise and vibration. In addition, open-pit mining that removes the topsoil can consequently cause damage to neighboring residential areas due to slope failures.

- ③ Occupational health and safety

Due to elevation difference of the topography at the mining site, the use of heavy equipment and falling may lead to injuries. Depending on the mine excavation methods, there can be accidents such as tunnel collapse, heavy object falling, and suffocation. Most safety accidents at the mining site are likely to lead to death, so it is required to ensure work safety.

- ① Environmental Impact

- (2) Relevant Industry

- ① Coal Mining

It includes all forms of coal mining.

- ② Mining of valuable minerals

Regardless of the mining method, this includes minerals such as iron and copper, minerals such as precious metals and rare earth metals.

- ③ Mining of Construction Materials

This is the mining of aggregate, stone, limestone (cement raw material) regardless of the mining method used.

- ① Coal Mining

- (3) Korea Standard Industry Classification (from 10th revision notification)

- Classification codes and item names are based on the sub-category.

Classification Code Item Name B0510 Coal Mining B0610 Iron Mining B0620 Nonferrous metal Mining B0711 Limestone and Clay Mining B0712 Collecting stone, crushed stone and sand, gravel B0721 Mining of minerals for chemicals and fertilizer raw materials B0729 Other non-metallic mineral mining - (4) Monitoring Items

- Scattering dust control

- Range that is under the influence of scattering dust

- Water consumption

- Wastewater quality management

- Soil and groundwater contamination

- Treatment of mine waste such as mine tailings

- Ambient noise and vibration damage

- Project area

- Impact on ecosystem

- Worksite safety equipment

- Emergency response system

5. Crude Oil & Gas Development Project

- (1) Risks

- ① Environmental Impact

The development of crude oil and gas is divided into offshore drilling and onshore drilling. The major risk is the leakage of crude oil into the sea or soil. Longer pipelines are needed for drilling and mining of crude oil. The longer the length of the pipeline, the higher the likelihood of leakage and scattering of crude oil due to pipeline damage and poor connection. In particular, crude oil leaks from underground pipelines cannot be identified immediately, compared with leaks on the ground surface. Therefore, it takes a lot of time and costs to recover the damage.

In order to extract crude oil and gas, drilling is to be performed at depths of 5 km or more to the reservoir. Drilling Mud (also called Drilling Fluid, hereinafter may be referred to as "muddy water") is used to prevent frictional forces from acting and the collapse of boreholes when crushing rock formations. Drilling mud itself contains chemicals such as stabilizers and viscosity reducers. The used drilling mud, the fractured rocks and soil that are produced as a result of drilling include deep groundwater with high salinity and crude oil. During the treatment of these wastes, it may have contaminated the surrounding soil and groundwater.

- ② Greenhouse gas emissions

Exploration and drilling activities for crude oil and gas development cannot be deemed as greenhouse gas emissions. However, the crude oil and gas development industry can be regarded as one of the major industries related to greenhouse gas emissions, since a considerable amount of crude oil and natural gases produced as a result of drilling are consumed as fossil fuel for thermal power generation.

- ③ Occupational health and safety

When developing crude oil and gas, one is likely to be exposed to dangerous work environments such as high-altitude work, isolated work, and heavy equipment work. When storage of collected crude oil and gas, a small fire may spread to a large explosion, and hence thorough management is imperative.

- ① Environmental Impact

- (2) Relevant Industry

- ① Offshore oil and gas development

It refers to the case where crude oil and gases are developed using drilling rigs and floating facilities at sea.

- ② Onshore crude oil and gas development

It refers to the case where crude oil and gases are developed using drilling equipment on the land.

- ③ Production of liquefied natural gas

It refers to the impurity removal and liquefaction facility for the mined natural gas.

- ① Offshore oil and gas development

- (3) Korea Standard Industry Classification (from 10th revision notification)

- In the Korean standard industry classification, it is named as "crude oil and natural gas mining business" and there is no classification according to the drilling location. Classification codes and item names are based on sub-sub categories.

Classification Code Item Name B05200 Crude oil and natural gas mining - (4) Monitoring Items

- Safety management of crude oil & gas pipelines and tanks, including the drilling pipes

- Waste and wastewater treatment

- Site environmental impact and pollution management of soil, groundwater, and sea water

- Safety and health measures taken for workers involved in drilling and mining operations

6. Construction Works of Large-scaled Infrastructure Facilities

- (1) Risks

- ① Environmental Impact

Construction projects that require large-scale sites, such as ports, airports, industrial complexes, and highways, may have problems arising from the scattered dust and construction waste generated during construction work.

When carrying out the construction works of large-scale tank terminals (large-scale storage of crude oil and liquid chemicals) and oil pipeline, the causes that could not have been recognized at the time of construction can result in environmentally adverse effects. In particular, for large-scale storage and cargo facilities of crude oil and chemicals, there are many instances where the facility is constructed near the pier for the efficiency of transportation operation, which may in turn lead to marine pollution.

- ② Adverse Impact on Local Communities and Habitats

In cases where the residential area is adjacent to the site of large-scale infrastructure construction project, there can be inconvenience caused due to construction noise and vibration for a long period of time.

Construction of large-scale infrastructure such as highway, tunnel, and railway construction may result in the destruction of natural habitats, followed by subsequent negative impact on ecologies. The purchase of a wide range of land may also lead to involuntary relocation of residents in the area.

- ③ Occupational health and safety

It is necessary to pay attention to workers’ safety accidents which are caused by the handling of heavy equipment and heavy vehicles during large-scale construction projects. Frequent entry of construction vehicles can affect traffic safety in the surrounding areas.

- ① Environmental Impact

- (2) Relevant Industry

- Construction of large-scale national infrastructure including airports, industrial complexes and ports

- Construction of major transportation networks including highway, railway, tunnel

- (3) Korea Standard Industry Classification (Tenth revision notification standard)

- In the sub-classification of Korea Standard Industrial Classification, it is named as "civil engineering facility construction works". Classification codes and item names are classified by the following subcategories.

Classification Code Item Name F41221 Road Construction Business F41222 Bridge, Tunnel and Rail Construction Works F41223 Construction of Harbor, Waterways, Dam and similar structures F41225 Construction of Industrial Production Facilities F41229 Other Civil Structure Construction - (4) Monitoring Items

- Scattering dust control

- Disposal of construction wastes

- Impact of ambient noise and vibrations

- Impact on natural habitats and ecosystems

- Consent of stakeholders at the construction site

- Measures towards workplace safety, health and traffic safety

- Management of environmental impact relevant to the storage of hazardous substances or underground pipelines

7. Power Generation Industry

- (1) Risks

- ① Environmental Impact

(Thermal Power) In addition to greenhouse gas emissions, combustion of fossil fuels has a significant impact on the generation of air pollutants. There may be the emission of harmful hydrocarbons, including but not limited to: the generation of sulfur oxides due to the combustion of sulfur present in the fuel, the generation of nitrogen oxides due to the high temperature combustion, the direct generation of particulate matter produced by the secondary generation from sulfur oxides, nitrogen oxides, and carbon monoxide emissions due to their incomplete combustion. In particular, for coal-fired power generation, the problem caused by air pollutants is more serious than other fossil fuel sources, so one needs to pay particular attention to the environmental impact due to this method.

(Nuclear power generation) Nuclear power generation has the advantage of high power production efficiency and limited emission of air and water pollutants, but the storage and treatment of the generated radioactive waste is difficult and can cause serious environmental problems if not properly treated. In addition, nuclear accidents in nuclear power plants may lead to disasters spread even to the neighboring countries, beyond just the environmental adverse effects caused by fires and explosions. Therefore, nuclear power generation is an industry that needs to constantly monitor its thorough maintenance.

- ② Greenhouse Gas Emissions

(Thermal power generation) Thermal power generation consumes fossil fuel. Due to the nature of the fuel used, it is inevitably accompanied by a problem of carbon dioxide emissions, which is a combustion product. Natural gas generation, which is classified as relatively clean energy, has a very low emission of pollutants such as sulfur oxides, nitrogen oxides, and particulate matter compared with coal power generation, but there is also a risk of greenhouse gas emissions.

- ③ Adverse Impacts on Local Communities and Habitats

(Hydroelectric power generation) Hydroelectric power generation is a clean power generation method with little pollutant discharge, but it requires a large-sized project site for hydroelectric power generation, as found in large-scale dams and reservoir construction. During the construction of hydroelectric power plants, involuntary migration of inhabitants from inundated areas may occur, and natural habitats, land and aquatic ecosystems may be disturbed by artificial structures and artificial lakes.

(Solar power generation) Solar power generation is the cleanest power generation method with little environmental impact from greenhouse gas emissions and pollutants. However, due to the low power production efficiency, it is necessary to construct a large site to install solar panels, if high power is to be produced. Similar to the case of hydroelectric power generation, there may be an adverse impact on local communities and habitats in the construction of large-scale solar power plants as well.

- ① Environmental Impact

- (2) Relevant Industry

- Thermal power generation using coal, oil, and natural gas

- Hydroelectric power generation using the falling water and flow of water, such as dams, reservoirs, tidal power, wave power generation, etc.

- Nuclear power generation using radioactive fuel

- Large scale solar power generation

- (3) Korea Standard Industry Classification (Tenth revision notification standard)

- In the sub-classification of Korea Standard Industrial Classification, it is named only as "power generation" with no regard to the type of power generation.

Classification Code Item Name D35111 Nuclear Power Generation Industry D35112 Hydropower Generation Industry D35113 Thermal Power Generation Industry D35114 Solar Power Generation Industry - (4) Monitoring Items

- (Thermal power) Emission concentration and emission amount of air pollutants

- (Thermal power) Establishment and management of air pollution prevention facilities

- (Nuclear power) Planning and treatment of radioactive waste to be disposed of

- (Hydroelectric power) Consent from stakeholders in the flooded areas

- (Hydroelectric power) Impact on natural habitats and ecosystems

- (Large-Scale Solar Power) Consent from relevant stakeholders on project site

- (Solar power) Impact on natural habitats

8. Waste and wastewater treatment business

- (1) Risks

- ① Environmental Impact

(Wastewater) Wastewater that has been treated at the relevant facility is often discharged directly into the water system, when it is treated professionally (wastewater treatment company, waste water treatment plant in industrial complex, etc.). Effective wastewater treatment methods and chemicals may vary depending on the main pollutants (BOD, COD, pH, T-N, T-P, etc.) of wastewater. However, due to the fact that it is released immediately into the water system, serious water pollution can occur if not properly treated.

(Wastewater) When using coagulants and other processing chemicals in wastewater treatment, sludge type wastes are generated. The sludge generated as a result of wastewater treatment contains a large amount of pollutants such as organic substances and heavy metals already present in the raw wastewater. Therefore, environmental impact on the surrounding lands and water bodies may occur during the process of sludge dehydration, incineration and landfilling.

(Waste) There are various ways to treat waste, but it can be divided into recycling, incineration and landfill. In addition to the problem of greenhouse gas emissions when incinerating waste, air pollutants such as carbon monoxide and dioxins can prove to be fatal to the human body. Soil and groundwater contamination due to leachate may occur at the time of landfilling of the waste. The pollution of landfill cannot be experienced immediately because of the nature of underground pollution, and the scale of pollution damage and the cost of restoration can be significant.

(Transport) When transporting wastewater and wastes to the vehicle, vehicle accidents during transport can cause considerable environmental impacts around the accident area. If an accident occurs on public roads due to the overturning or collision of a vehicle that carries wastewater or liquid waste, unlike an accident at a waste disposal facility equipped with an appropriate damage prevention facility, it can have a devastating effect on the surrounding area.

- ② Greenhouse gas emissions

(Waste incineration) During the incineration of waste, it is necessary to use fuel to create a high temperature for incineration. Since greenhouse gas emissions, from using fossil fuels, are substantial and greenhouse gases are generated during the burning process of waste itself, it needs caution to be implemented in terms of GHG emissions management.

- ① Environmental Impact

- (2) Relevant Industry

- Wastewater treatment business, stakeholders such as wastewater treatment plant, wastewater treatment contractor

- Disposal of waste such as waste incineration and landfill

- Waste water and waste transportation business

- (3) Korea Standard Industry Classification (from 10th revision notification)

- Classification codes and item names are based on the sub-classification.

Classification Code Item Name E3701 Sewage and Wastewater Treatment Business E3811 Non-designated waste collection and transportation business E3812 Designated waste collection and transportation business E3813 Collection and transportation of construction waste E3821 Non-designated waste treatment business E3824 Collection, transportation and disposal of radioactive waste - (4) Monitoring Items

- Treatment of wastewater and by-products (sludge, ashes, etc.) from wastewater and waste treatment

- Preventing leakage while transporting wastewater and waste

- Reduction of harmful substances, such as dioxins, when incinerating wastes

- Preventing the pollution of surrounding soil and groundwater during landfill

9. Weapons and Military Supplies

- (1) Risks

- ① Social Impact

(Adverse Impacts on Local Communities and Habitats) Cluster Bomb is a weapon that indiscriminately destroys a large area, with small bombs scattered in quantities of two to three to as many as two thousand bombs in one bomb. It is a well-known shotgun-type bomb used for the purpose of destroying and killing many humans indiscriminately. It is called a spreading gun or a Moja (mother and child) bomb, and the unexploded unburnt guns remain long afterwards and act like landmines. The Islands of Laos, after 40 years since the end of the war, are still experiencing 50 casualties each year because of these.

Cluster bombs are defined as anti-human weapons by international communities, such as the United Nations, along with anti-personnel landmines. In accordance with the principle of 'No investment in a lethal weapons manufacturing company', these pension funds in Europe, such as Norway, Sweden and the Netherlands, are serving as forces prohibiting from investing in this sector.

- ② Greenhouse gas emissions

(Waste incineration) During the incineration of waste, it is necessary to use fuel to create a high temperature for incineration. Since greenhouse gas emissions, from using fossil fuels, are substantial and greenhouse gases are generated during the burning process of waste itself, it needs caution to be implemented in terms of GHG emissions management.

- ① Social Impact

- (2) Relevant Industry

- Weapons and Military Supplies

- (3) Korea’s Standard Industry Classification (from 10th revision notification)

- Classification codes and item names are based on sub-classification.

Classification Code Item Name C2520 Manufacturing Weapons, Bullet, and Cannon Balls - (4) Monitoring Items

- Product manufacturing activities

- Interactions with major stakeholders

- Vision & Strategy

10. Drift-net Fishing

- (1) Risks

- ① Environmental Impact

(Biodiversity loss) Large-scale over-exploitation of a particular species results in an imbalance in the marine ecosystems. Large-scale overfishing is a key factor that damages marine ecosystems, such as catching fragile species (such as tuna, sharks, sea turtles, and other marine species) or neglecting marine debris. It can also cause a sustainability issue for local residents whose main livelihood is fishing.

- ② Social Impact

(Human Rights) The human rights of seafarers are being illuminated in the aftermath of a violent incident on a ship due to religious and cultural differences, in a deep-sea fishing boat where seafarers from various countries live together. In order to improve the human rights of the seafarer in the deep-sea fishing vessel, the government is taking measures such as heavy penalties for the assault conducted on the ship, canceling the permission of the deep-sea fishery for major illegal activities, and suspending government subsidies. However, it is necessary for companies to establish a policy or system for the protection of human rights of the seafarers by themselves.

- ① Environmental Impact

- (2) Relevant Industry

- Large-scaled drift-net fishing

- (3) Korea Standard Industry Classification (from 10th revision notification)

- Classification codes and item names are based on sub-classification.

Classification Code Item Name A0311 Sea surface fishery A0312 Inland water fishing - (4) Monitoring Items

- Survey on forced labor

- Protection of workers’safety

11. Cigarettes

- (1) Risks

- ① Environmental Impact

The tobacco industry affects not only smokers but also non-smokers indirectly, and has contributed a great impact on the destruction of the global environment, such as forest destruction.

(Soil, Groundwater) Because cigarettes are sensitive to insects and diseases, excessive amounts of pesticides, herbicides, and fertilizers are added to nearby crops, causing ground pollution problems due to soil contamination. In particular, the waste of cigarette butts is not decomposed naturally by microorganisms. A cigarette contains about 4,000 chemical components . And from there on, when it is introduced into soil, sea, river or lake by rainwater, it can lead to the death of birds and animals that have eaten the debris.

(Forest) During the process of drying the tobacco leaves, massive logging and fire caused by cigarette butts can destroy or damage the forests. After harvesting, the tobacco leaves should be dried at high temperatures for about a week for the purpose of storage and transportation, which will be followed by massive logging. One (1) hectare (ha) land, is used for one drying process, and more than 5 million hectares (about 600 million trees) are cut annually. Also, since paper is used to wrap the tobacco leaves, the amount of deforestation becomes much larger in scale.

- ② Occupational Safety and Health

As nicotine is absorbed through the skin during the time of tobacco harvest, it often causes, acute nicotine addiction the called 'green tobacco sickness' (GTS). Headache, dizziness, and nausea are common symptoms. It occurs mainly at the time of post-harvest cigarette drying.

Tobacco leaves are sensitive to insects and diseases, which means that pesticides, herbicides and fertilizers are over-used, in comparison to other crops. Nevertheless, it is rare to wear protective gear for economic reasons, even when protective equipment is essential. In Africa, Asia, and South America, there may be additional issues such as child labor.

- ① Environmental Impact

- (2) Relevant Industry

- Tobacco manufacturing (tobacco redrying, etc.)

- (3) Korea Standard Industry Classification (from 10th revision notification)

- Classification codes and item names are based on subcategories, and industries in parentheses are sub-sub-categories.

Classification Code Item Name C1200 Tobacco Manufacturing (Tobacco Redrying) C1200 Tobacco Manufacturing (Tobacco Manufacturing) - (4) Monitoring Items

- Control of soil pollutants

- Level of pollution of water pollutants

- For large-scale logging, the impact on local habitat and ecology

- See whether the logging areas and habitats of protected plant species are included in the logging site

- Fire prevention measures

- Safety and health measures taken for the workers

- Minimization of raw material input, reuse and increase recycling rate

12. Coal Processing

- (1) Risks

- ① Environmental Impact

(Air Pollutant) During the refining, liquefaction and gasification plans of the initially mined coal, the impurities present in the coal are removed. In this process, air pollutants such as mercury carbon monoxide, hydrogen sulfide, carbon disulfide, ammonia and hydrogen cyanide are generated. Some of these react with the atmosphere to produce ozone and ultrafine dust, which accelerates climate change. Furthermore, it can damage the cardiovascular, nervous system and respiratory system of the local residents exposed to pollutants.

(Soil and water pollutants) During the process of burning, the coal that is mined is washed to remove impurities. The wastewater generated at this time is coal slurry. This wastewater is stored in a slurry reservoir, but it can contaminate the soil and groundwater if it is leaked. In addition, the process of burning coal, sulfate and nitrate emissions may cause acid rain, damaging rivers, forests, crops and soils.

- ② Social Impact

It can cause legal and social conflicts in the process of forcing residents to forest areas to develop the coal mines. In addition, it has elements that could threaten the safety of the workers and local residents due to problems such as chemical emissions and radiation exposure during the mining and smelting of certain metals.

- ① Environmental Impact

- (2) Relevant Industry

- Purification of coal to consequently produce coal and industrial coke, to be used for fuel

- Coal liquefaction and gasification facility

- (3) Korea Standard Industry Classification (from 10th revision notification)

- Classification codes and item names are based on sub-classification.

Classification Code Item Name C19101 Manufacturing Cokes and Briquettes - (4) Monitoring Items

- Scattering dust emission management

- Ambient impact range due to the scattering dust

- Waste water quality management

- Soil and groundwater contamination

- Treatment of mine wastes such as mine tailings

- Ambient noise and vibration damage

- Project area

- Worksite safety equipment

- Emergency response system

3.1.3. Management Methods

The Holding Company will select the areas of interest for the whole Group, and confer with Subsidiaries about monitoring and other management methods.

Each Subsidiary’s risk management department will select areas of interest based on the Subsidiary’s characteristics in addition to the Group-wide areas of interest, and carry out monitoring of issues for specific areas, such as exposure, asset quality, etc. in the chosen areas of interest. The Subsidiary’s risk management department will report the results of its monitoring to the Holding Company’s risk management department.

3.2. Financing Exclusions and Conditions

For areas of interest that have a serious environmental or social impact, the Group will either exclude them from financing or establish conditions for financing.

3.2.1. Exclusions to Financing

The Group excludes the following illegal activities from financing.

- Transactions that involve the production of products or provision of services that violate the applicable country’s laws or regulations.

- Transactions involving illegal gambling/pornography industries.

- Transactions involving the production or trade of radioactive matter. However, allowances can be made for power production, medical purposes, and other cases where proper protection and management are deemed possible.

3.2.2. Conditional Financing

The Group operates conditional project financing for coal-fired power plants based on criteria that it established in consideration of recent global issues related to fossil fuel use, such as climate change and particulate matter emissions. Project financing for the construction of new coal-fired plants in Korea or another OECD country will only be granted if the technology or CO2 emissions satisfy a certain level of standards.

- Financing is possible with technology at or above supercritical level, or when CO2 emissions are below 800g/kWh.

| ‹ Reference › CO2 Emissions by Energy Source | ||

|---|---|---|

| Type | Generation Method | CO2 Emissions (g/kWh) |

| Coal | Coal gasification | 640~760 |

| Ultra super critical (USC) | 676~795 | |

| Super critical (SC) | 756~836 | |

| Subcritical | 807~907 | |

| Heavy Oil | Heavy oil power | 449~505 |

| Gas power | 505~561 | |

| Gas | Combined cycle gas power | 355 |

3.3. Environmental & Social Risk Review

For large-scale, long-term project financing transactions that have a major impact on the environment or society, the Group will apply its Environmental & Social Risk Review process to identify the risks and evaluate the impact of the project, which will then be reflected in the investment decision.

3.3.1. Applicable Subjects

The Environmental & Social Risk Review applies to project financing excluding regular corporate loans, and includes investments in the form of funds that can be reviewed and controlled from an environmental and social perspective.

Details about the applicable subjects that depend on the domestic/overseas region or the project amount will follow specifications defined in the work manual.

3.3.2. Review Process

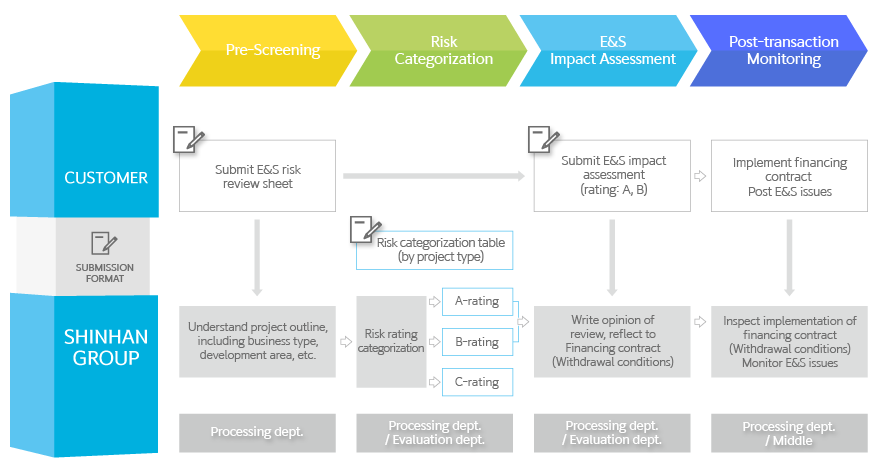

The Environmental & Social Risk Review process consists of four steps: pre-screening, risk categorization, environmental & social impact assessment, and post-transaction monitoring.

- Pre-screening : Review of whether the project is in accord with the Group’s environmental and social risk management policies; understanding of the business, including project type, purpose, region, etc.

- Risk categorization : Categorization of risk level according to environmental and social impact, taking into account each project’s characteristics. Risk levels are divided into A, B, and C ratings based on information gained during pre-screening.

- Environmental & social impact assessment : Evaluation and inspection report of specific environmental and social impact of projects with A- or B-ratings; if risk factors require mitigation measures or management action, this must be reflected in the financing contract and managed.

- Post-transaction monitoring : Inspection of whether the mitigation measures to minimize environmental and social impact are being implemented; monitoring of environmental and social issues while project is in progress.

A-rating : Project has serious environmental or social risks with the potential for widespread dispersal in the region.

B-rating : Risks are less serious than A-rating and confined to the site of the project; it is easy to carry out mitigation or recovery measures.

C-rating : Environmental and social risks are negligible.

[Environmental & Social Risk Review Process]

4. Information Disclosure

The Group will publically disclose the main contents and results of its environmental and social risk management policies as part of its efforts to communicate with diverse stakeholders and improve transparency.

5. Reinforcement of Capabilities

Through a variety of education and training programs about the Environmental & Social Risk Management Policy Framework, the Group will persist in its efforts to boost employee participation and strengthen environmental and social risk management capabilities across the Group.